Services

Welded Tank Design & Fabrication

PRT is a market leader in the construction of large-scale carbon steel welded tanks and stainless steel liquid storage tanks for a wide variety of industries. PRT offers turnkey, start to finish operations with complete in-house engineering, design, fabrication, erection, and coatings capabilities.

SB54 COMPLIANT

On-Site Preparation & Installation

CSE specializes in site grading, mechanical/piping, concrete, demolition, underground utilities, bypasses and final site work.

SB54 COMPLIANT

National Union Tank Contractor

ATC is a national full service union tank labor contractor delivering skilled Union labor for welded tank installations, repairs, and industrial coating.

SB54 COMPLIANT

Domes, Roofs & Seals

Ultraflote-Domes, Roofs & Seals provides Aluminum Geodesic Dome advanced Tank Cover Technology and Internal Floating Roofs for petroleum, municipal, and industrial applications.

SB54 COMPLIANT

All Types of Tanks

Bolted Tanks

Pump Houses & Paving

Our Work

Award Winning Projects

7157 Digester Gas Storage Replacement – City of San Jose, CA

Year Completed: October 2015

Capacity: 50,000 cu. Ft

Description:

This 50,000 cu. Ft. Low pressure gas holder was a replacement to a smaller unit at the facility. The treatment plant needed increased capacity with limited space, and so had to install this new gas holder in the same area originally occupied by the older unit.

This unit provides necessary capacity for increased demand from daily operation of the plant.

The city’s specification required that the gas holder be designed for an initial operating pressure of 6½ inches water column and to be able to accommodate an increased future operating pressure of 14 inches water column. The piston deck was designed to accommodate the future placement of additional ballast for the increased pressure.

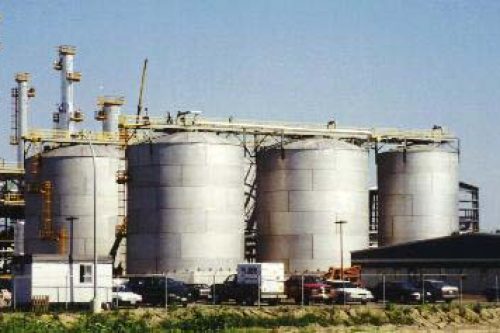

Two 7.9 MG Equalization Tanks – Orange County Water District

Project scope included provided engineering, fabrication, erection and coating of two (2) 7.9 million gallon welded steel reservoirs. Foundation design for each tank required 449 concrete piles 60 to 65 feet deep, due to ground soil having extremely high liquefaction potential during a seismic event.

The project takes highly treated wastewater and purifies it through a three-step process that includes micro-filtration, reverse osmosis and ultraviolet light with hydrogen peroxide and then uses it to recharge the groundwater basin. It is the world’s largest advanced water purification facility of its kind prior to this expansion project, producing up to 70 million gallons of new water every day.

Each tank is 216 ft. diameter x 32 ft. shell height with a three bay roof structure. Construction of the two tanks utilized over 1,380 tons of steel. Both tanks were shop blasted and primed prior to field application of high performance 100% solids coating system on the full interior. It is estimated that the life-cycle of the tank coatings is 50 years.